Production of the 1900hp Pininfarina Battista hyper GT commences in Italy

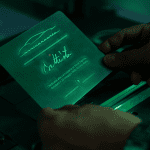

Commissioning a Battista requires you to go through 13.9 quintillions and 128 million colour combinations for the exterior and interior respectively

You might be mistaken if you thought the art of coachbuilding was long forgotten in the World War era. Luxury carmakers like Rolls Royce and Bentley are resurrecting the overlooked practice of coachbuilding to cater to the bespoke demands of their customers. And joining the coachbuilding bandwagon is luxury hypercar-maker Pininfarina as it announces the commencement of production of the Battista.

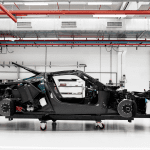

Pininfarina will build the Battista, Italy’s most powerful production car yet, in the dedicated new Atelier space in Cambiano, located in the Piemonte region of Italy. Named the Battista Atelier space, the facility has been revamped to suit Battista’s hand-made production and also houses a commissioning lounge space for its customers.

Each of the 150-unit-only Battista will go through a 10-week-assembly process from start to finish. Ten craftsmen assemble each individual Battista, taking more than 1,250 hours. The special-edition Battista Anniversario, with a five-unit build: all sold out, requires another 18 week-extended schedule for its hand-painted finish. The bespoke design finishes rack up the assembly time further to 1,340 hours.

Placing an order for a Battista is a passionate experience. A bespoke design proposal is created for each client before they are invited to Cambiano to work face-to-face with the designers and refine their personalisations. Upon visiting the Atelier Space and its commissioning lounge, customers are greeted with a host of exterior and interior colours and various materials to review. Pininfarina claims there are up to 13.9 quintillion exterior combinations and 128 million interior colour combinations for the owner to choose between.

The Battista Atelier Space has divided its production process and quality assurance checks into 14 zones. The initial process sees the body being bonded with the monocoque chassis with a bespoke rig measuring every dimension and parameter to the finest tolerances. The body, then, gets dismounted to be moved to the paint facility, which is a three-four week affair.

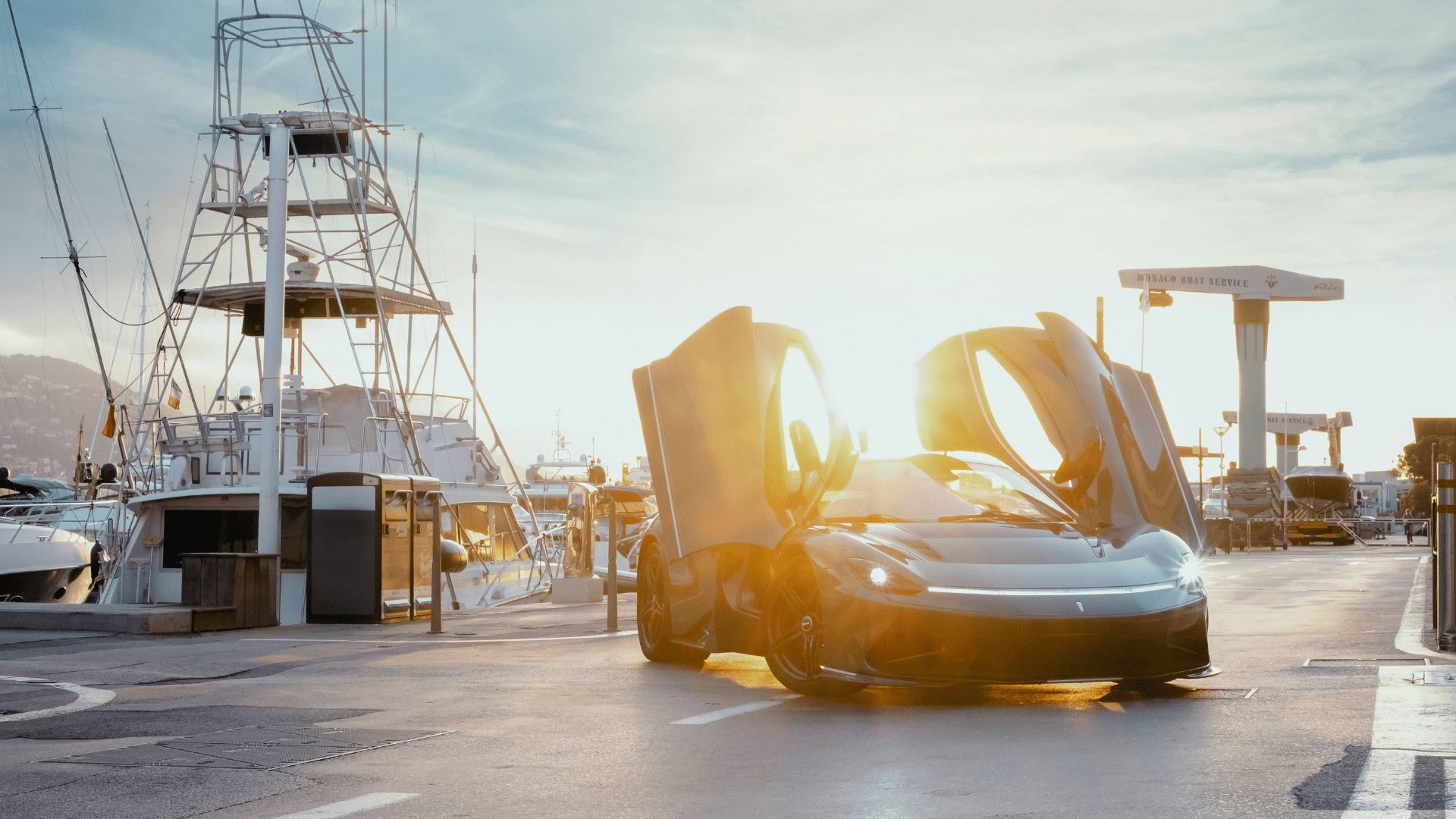

Eighty per cent of the vehicle gets assembled by the end of the fifth zone. Even the complex butterfly doors get installed at this stage that spans over the course of two days. The first end-of-line checks with bespoke software are undertaken next, comprising a 24-hour wheel alignment assessment and water leakage checks. A final end-of-the-line, including aesthetic evaluation in the light tunnel and on-road testing, is conducted before the car is readied for customer deliveries.

Every Battista customer gets guaranteed lifetime client services from Automobili Pininfarina. The firm provides 360-degree digital support for services like incorporating parts, warranty management, training and remote diagnostics. For specialist technical matters, a ‘flying doctor’ with an encyclopedic knowledge of the car will fly anywhere in the world to support the client and Battista. Moreover, three comprehensive aftersales packages are offered: Eccellenza, Futura and Eterna. These packages offer up to 10 years of an exclusive maintenance programme, an additional seven-year cover on the battery and powertrain warranty and a replacement body parts kit program that can be painted to the original specification in case of mishaps.

Deliveries to customers worldwide of Battista will commence this summer. The Pininfarina Battista electric hyper GT with 1900hp and 2,340 Nm torque is the most powerful Italian sports car in history.

Recommend0 recommendationsPublished in Cars, Green