The automobile industry has constantly been at the forefront of technological advancement and adaptations, whether it be adapting itself to new technology, market demands, or environmental demands, etc, the automotive industry leads the way in innovations and adopting those innovations to move forward.

Currently, the world is sitting at the threshold of one such innovation and technological advancement that is set to change the course of our future, regardless of the industry. Artificial Intelligence have force us to reshape not only the way we think but also the way we apply our efforts and labour. AI was bound to touch the automobile industry, with manufacturers already finding ways to integrate AI in their products.

But one of the biggest sectors of the automobile world, the Car manufacturing, is getting a high-tech makeover, and a German car maker, Audi, is leading the charge with artificial intelligence. Instead of old computers scattered around factories, Audi has incorporated a smart cloud system and AI tools in its manufacturing plant to make production smoother, safer, faster and an all around effieicint operations. This means fewer mistakes, happier workers, and better cars rolling off the production line.

Why Is Audi Turning Factories into “Smart” Plants?

Traditional factories rely on bulky hardware that is hard to update and fix. Audi found a solution, and it’s simply move the control to the cloud-based systems. Their Edge Cloud 4 Production (EC4P) system, designed by Audi’s own production and digitalisation team.

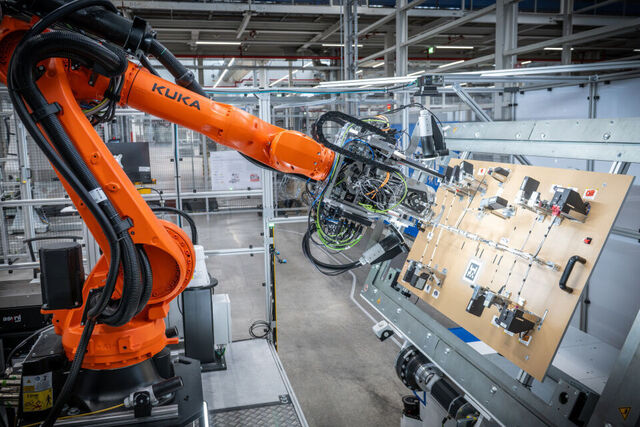

The system replaces traditional industrial PCs on the shop floor with a centralised, cloud-style server architecture. Letting robots and machines talk to each other seamlessly, like a well-oiled team. while the human employees are provided with real-time production data on their screens, guiding them on which vehicle model and features to assemble next. The shift has removed over 1,000 industrial PCs from Audi’s German factories, reducing costs and improving overall operational reliability.

At the Neckarsulm plant in Germany, where Audi builds A5 and A6 models, EC4P shines. About 100 robots sync up via virtual controllers in the cloud, working with split-second timing.

What is Audi’s Weld Splatter Detection System?

Weld Splatter Detection system is Audi’s smart, automated robotic system that effectively replaces one of the difficult jobs at car manufacturing facilities. Imagine grinding hot metal splashes off a car frame all day; that’s a rigourous back-breaking work. Audi’s AI spots these “weld splatters” with cameras, lights them up, and sends a robot to fix them. It’s part of Audi’s plan to let AI handle the dirty, dangerous tasks so human employees can focus on more skill-based work.

What is Smart Monitoring with ProcessGuardAIn?

It’s Audi’s Smart digital Monitoring system with ProcessGuardAIn designed to detect real-time production oversight, and spot problems before they turn into defects or downtime. It uses artificial intelligence to continuously monitor manufacturing processes such as welding, assembly, or automated production steps in real time and flags potential flaws before it manifests into serious issues. Improving overall production quality, reducing downtime, cuts waste to reduce manufacturing and production costs.

What does it mean for Audi’s customers and stakeholders?

Audi’s use of AI benefits customers and stakeholders alike by improving build quality and reliability while supporting safer and less demanding jobs for workers, and reducing energy use and hardware footprint across factories.